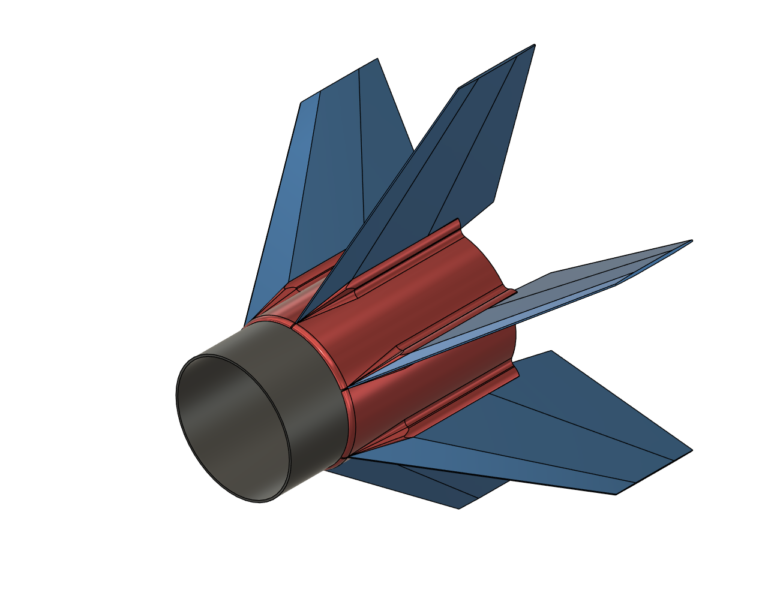

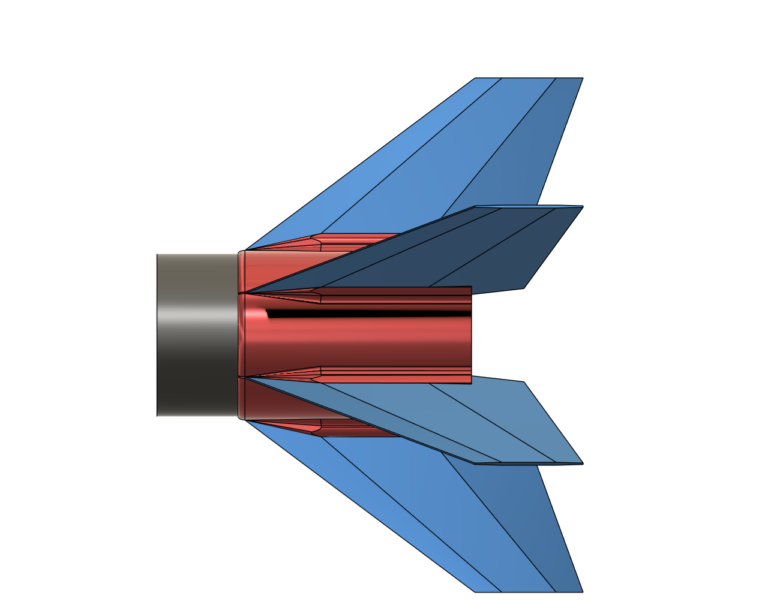

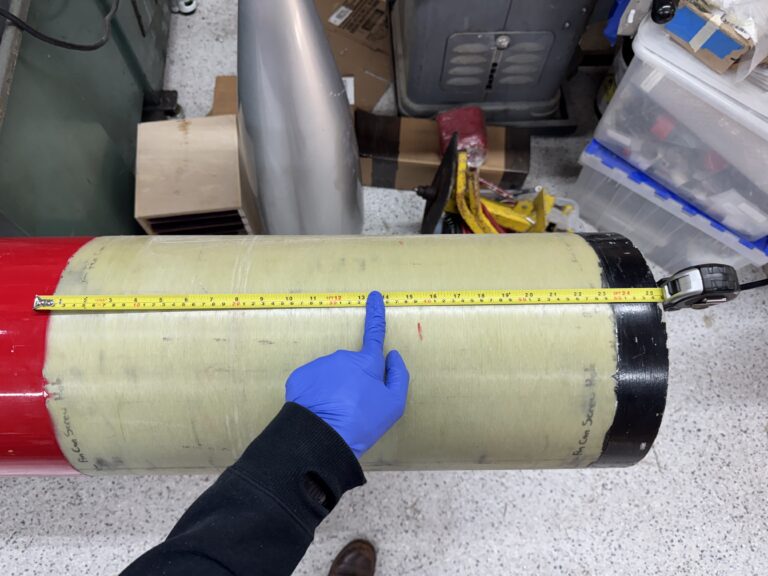

We had a small gathering at the Rocket Shoppe on Sunday 01/18/2026 to review the aft section / fin section of Red Ryder and specifically the inside. It gave us a better view of the internal stringer configuration – as well as the scale of this rocket.

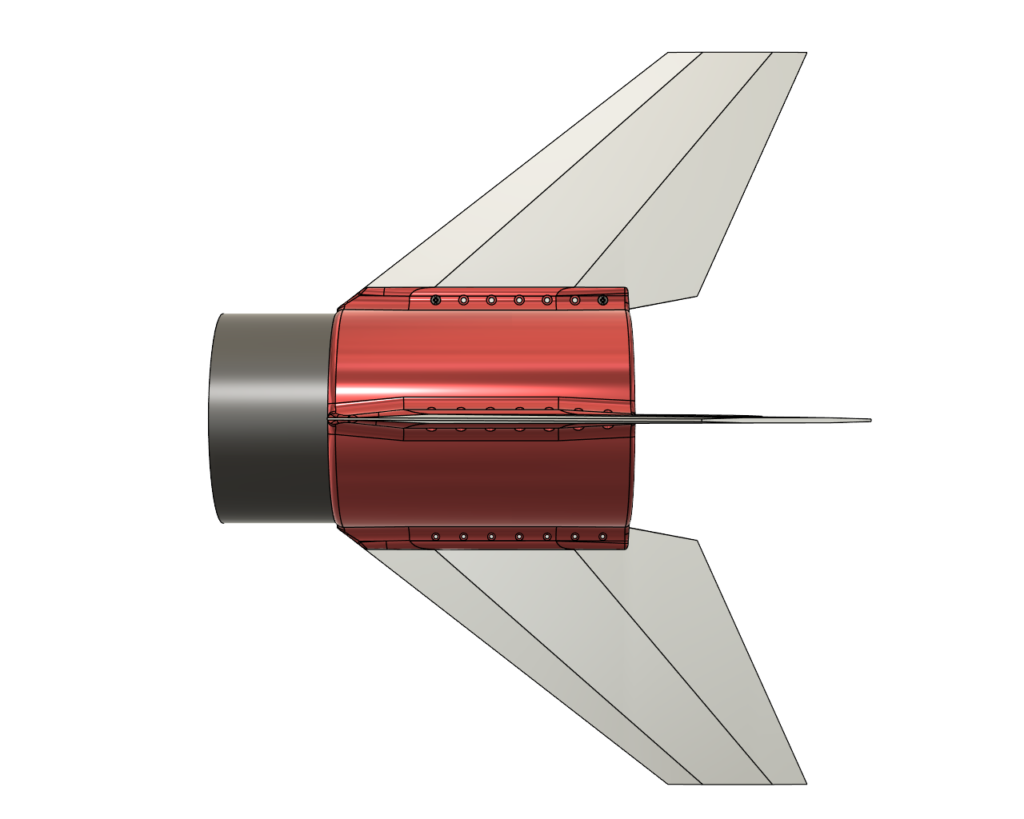

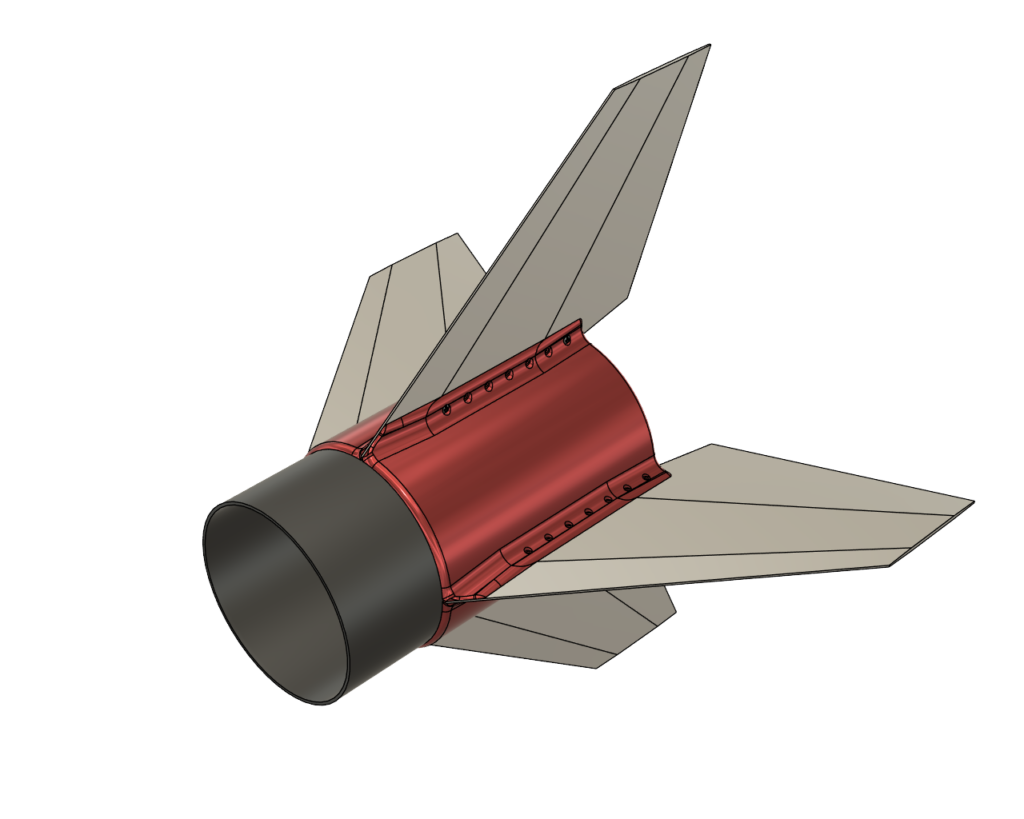

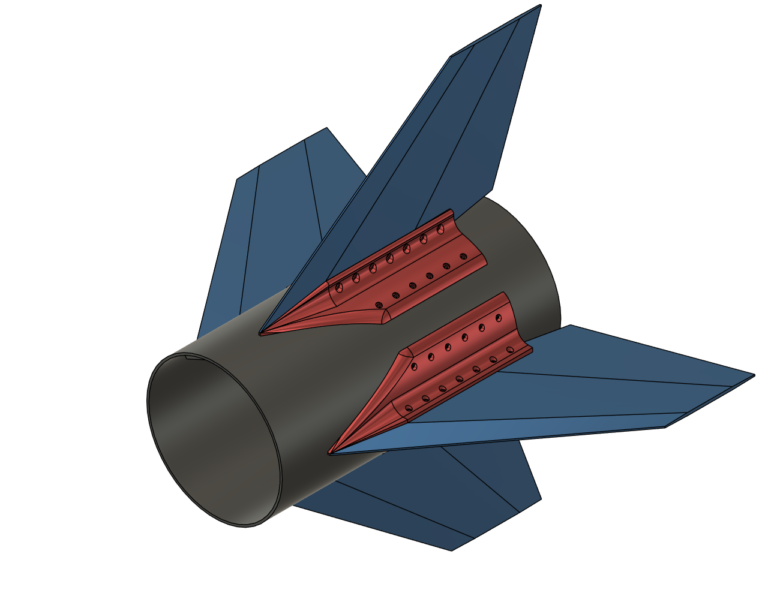

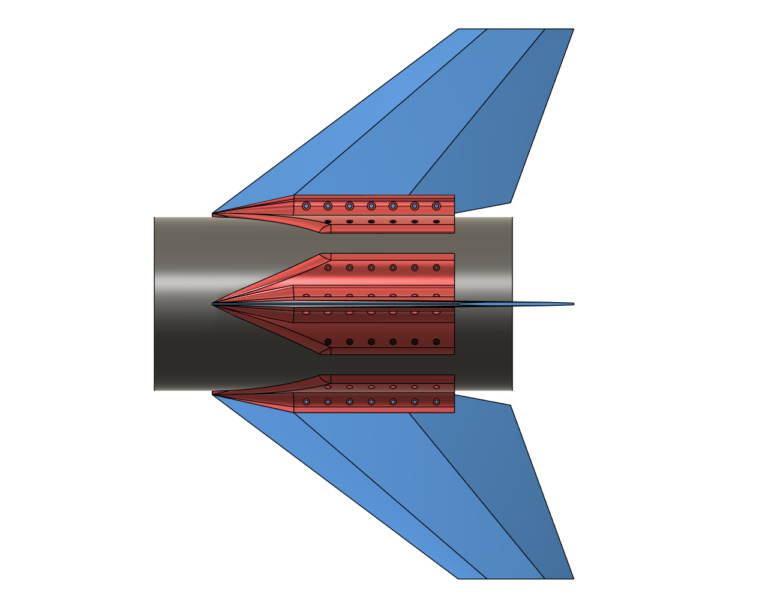

I came to the conclusion that the initial full modular / bracket fin assembly design was too big for my CNC manufacturing capabilities – the brackets would not fit into my work volume. Below are two alternative designs that would allow us to make a bracketed design.

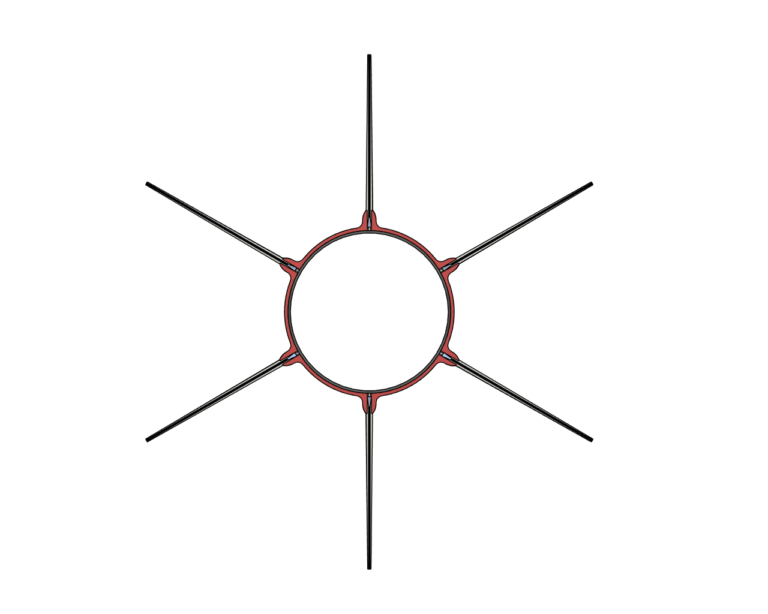

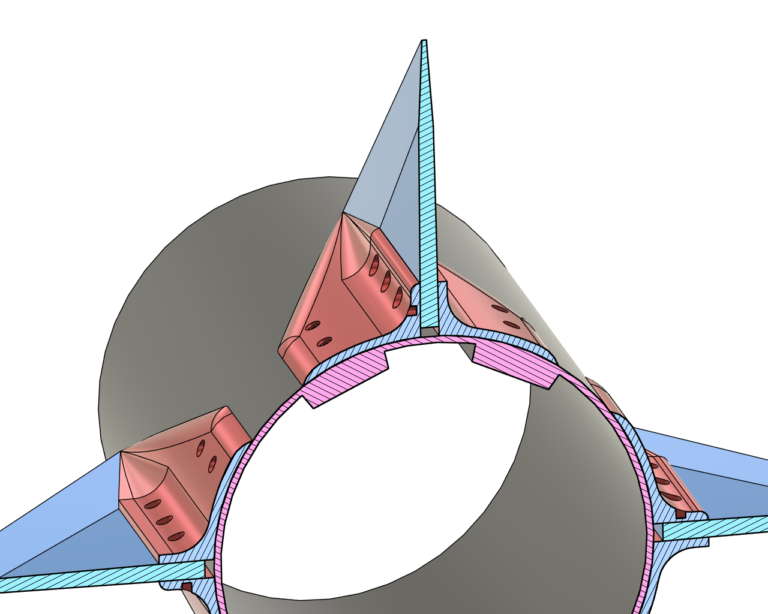

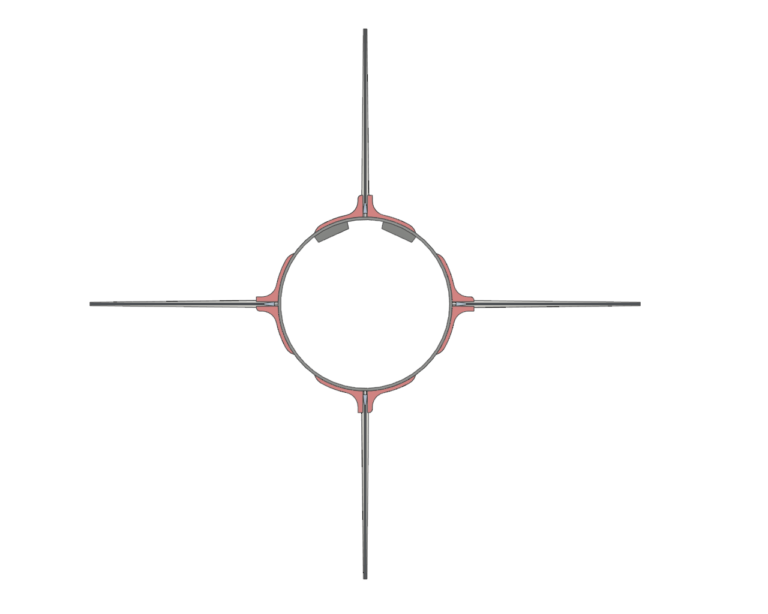

After reviewing RR’s after section- specifically the fin can area it was found that the internal stringers are arranged in such a way to allow us to bolt external fin brackets to the airframe – using these internal stringers as bolt supports. There is sufficient space to install aluminum backing plates as well and these back plates will distribute the clamping forces.

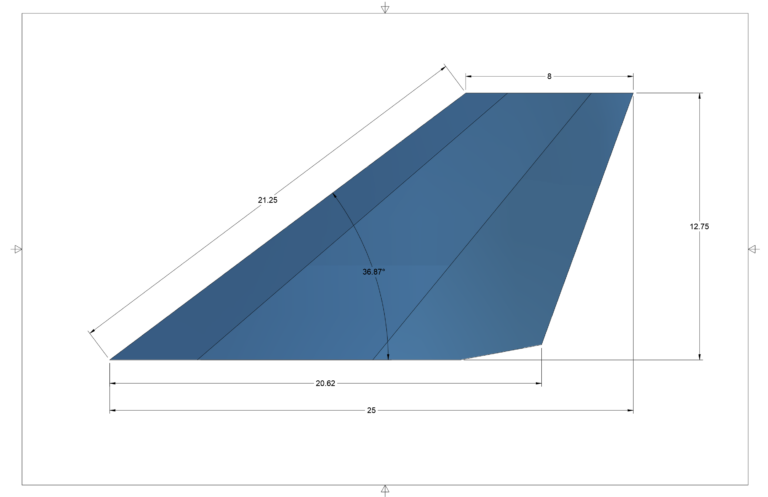

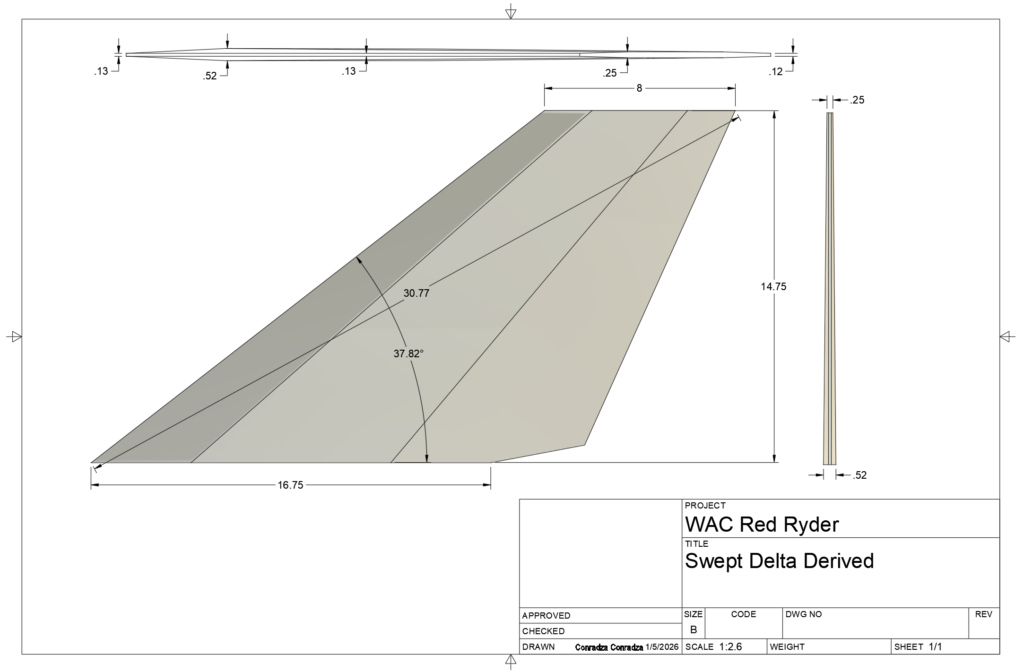

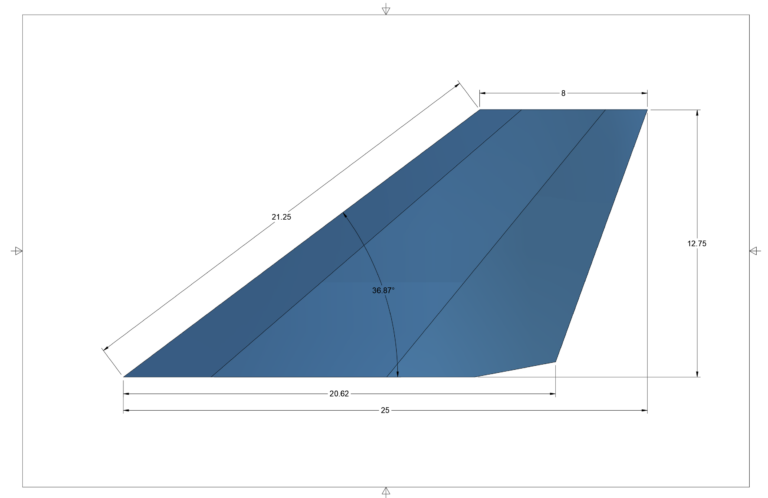

Fins are sized down slightly to allow us to machine these in the CNC mill IF that is the chosen path.

IF we do want a bracketed design where the brackets connect to each fin fully and run a radial clamp configuration then the only path forward would be to reduce the bracket sizes. The current brackets would not fit into the CNC work volume and more specifically the vices.

Reducing the bracket sizes means that this would need to turn into a 6-fin design. Adding two additional fins means we can reduce the size of the fins and make it easier to manufacture on the CNC mill IF that is the chosen path.