Calculations based on Swept Delta Profile – calculated fin volume of 66.745 in^3. Using industry “standard weight factor” in pounds per cubic inch.

All weight in pounds (lb)

1-Fin | 4-Fins | Rank | ||

Baltic Birch Plywood | 0.025 | 1.67 | 6.6745 | 2 |

Nomex Honeycomb Core* | 0.00174 | 0.12 | 0.464545 | 1 |

G10 Plate | 0.068 | 4.54 | 18.15464 | 4 |

Carbon Plate (QI) | 0.055 | 3.67 | 14.6839 | 3 |

6061 Aluminum | 0.0975 | 6.51 | 26.03055 | 5 |

7075 Aluminum | 0.102 | 6.81 | 27.23196 | 6 |

*Represents the NHC weight only and excludes the additional external lamination layer weight.

Basic core material cost – with dimensions that range between 0.375” x 24” x 48” and 48” x 48” depending on availability – based on Swept Delta Profile.

Unit | Total | Rank | |

Baltic Birch Plywood | $ 80.00 | $ 80.00 | 1 |

Nomex Honeycomb Core | $ 170.00 | $ 340.00 | 2 |

Nomex Honeycomb Pre-Laminated | $ 955.00 | $ 3,820.00 | 7 |

G10 Plate | $ 447.65 | $ 895.30 | 3 |

Carbon Plate (QI) | $ 1,112.32 | $ 2,224.64 | 6 |

6061 Aluminum | $ 65.71 | $ 262.84 | 4 |

7075 Aluminum | $ 136.00 | $ 544.00 | 5 |

Description | Core is Baltic Birtch Ply – 0.375” Sheets are cut into desired fin profile Both sides are then laminated with either Carbon or fiberglass cloth. Minimum of two layers on both sides with alternating fiber orientation. Recommended: Use vacuum bagging for lamination process. Baltic Birch is a high-quality, multi-ply hardwood plywood from Eastern Europe known for its exceptional strength, stability, and void-free core, made from thin, solid birch veneers. |

Strength Notes | The resultant laminate will be strong – since the BBPC is a ‘strong’ material and can be made stronger with additional fiber layers. Using vacuum bagging will ensure that all excess epoxy is drawn out – to further improve the strength to weight ratio. |

Advantages | Relatively cheap – the cost will be in the lamination process especially if vacuum bagging will be used – since there is additional cost in the equipment and consumables. Easy to manufacture.

Material Advantages

|

Disadvantages | Forming the fins to an exact aerodynamic profile is ‘nearly’ impossible Limited ‘bevels’ can be cut using a table saw – but it is a dangerous process that is prone to inconsistencies, especially at this scale/size. |

Weight | See table above |

Cost | See table above |

Application | Suitable for all construction techniques |

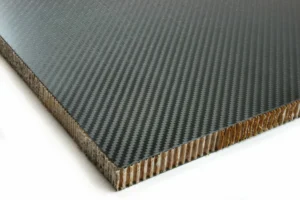

Description | Core is Nomex Honeycomb – likely 0.375” Both sides are laminated with either Carbon or fiberglass cloth. Minimum of two layers on both sides with alternating fiber orientation. Recommended: Use vacuum bagging for lamination process.

Validate: What is available in the Shop as it relates to thickness. If I remember correctly then it is the pure Honeycomb core without any external / side layers: we will likely need to add a thin layer of Birch ply to create a flat surface that can then be laminated. |

Strength Notes | The strength is purely in the outer layers provided by the carbon or fiberglass. Likely weaker than the Birch Play laminate since the NHC in itself is not strong. In essence an I-Beam, the honeycomb acting as the web, and the top skins acting as the flanges. The advantage over an I-Beam is the core creates a box structure giving the panel additional torsional rigidity. Another benefit of a core material is as the core thickness increases the panels stiffness increases dramatically. The Nomex honeycomb offers additional compressive strength with lower densities when compared to low density foam cores. Nomex Honeycomb also has properties including moisture resistance, energy absorption, and sound and vibration dampening. |

Advantages |

|

Disadvantages | Forming the fins to an exact aerodynamic profile is nearly impossible – even more so than the BPC. If you do cut limited ‘bevels’ using a table saw then that will effectively expose the NHC voids that will create an uneven surface and you expose the weak inner core. You are effectively weakening the NHC at the point where it will be subject to all the aerodynamic forces.

There could be an alternative where a hybrid aluminum / NHC fin is created to overcome this. See below. |

Weight | See table above |

Cost | See table above 1/5: If we have sufficient NHC available – then the cost is only in the laminate material & consumables.

|

Application | Suitable for all construction techniques |

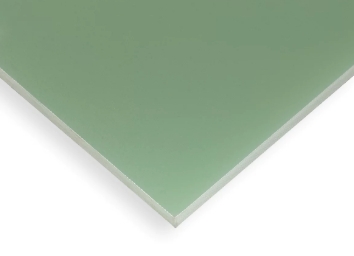

Description | Solid plate of G10 fiberglass purchased in 0.375” G-10 is a high-pressure fiberglass laminate, a type of composite material. It is manufactured by stacking multiple layers of glass cloth, soaking in epoxy resin, and compressing the resulting material under heat until the epoxy cures. |

Strength Notes | Ranging MSI: 1.8 – 4.2 |

Advantages | No additional lamination required |

Disadvantages | Forming the fins to an exact aerodynamic profile is ‘nearly’ impossible. Limited ‘bevels’ can be cut using a table saw – but it is a dangerous process that is prone to inconsistencies, especially at this scale/size. |

Weight | See table above |

Cost | See table above |

Application | Suitable for all construction techniques |

Description | Quasi-isotropic solid carbon fiber sheets are a tough and rigid carbon reinforced epoxy matrix composed of multiple layers of woven carbon fiber fabric without any core material. Quasi-isotropic sheets utilize balanced and symmetrical lay-up schedules of 90 degree and 45 degree fabric. |

Strength Notes | Standard 33MSI |

Advantages | Is lighter than G10 and significantly stronger – especially as a 0.375” plate |

Disadvantages |

|

Weight | See table above |

Cost | See table above |

Application | Suitable for all construction techniques |

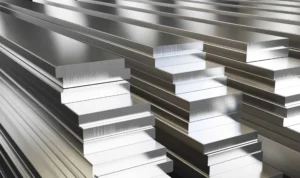

Description | Fully aerodynamic formed aluminum fins in 6061 – 0.375” root cord that tapers to 0.25” fin cord width. |

Strength Notes | |

Advantages | Can be fully CNC milled into the desired aerodynamic profiles. |

Disadvantages | Harder to work with as it relates to cutting and shaping Relatively heavy compared to other options |

Weight | See table above |

Cost | See table above – but excludes the interconnecting brackets (To be calculated) |

Application | Suitable for all construction techniques |