This should be a showcase of our teams’ abilities – arrive at BALLS34 with this infamous rocket and be proud of what we have built AND have a successful flight and recovery.

Criteria | Description |

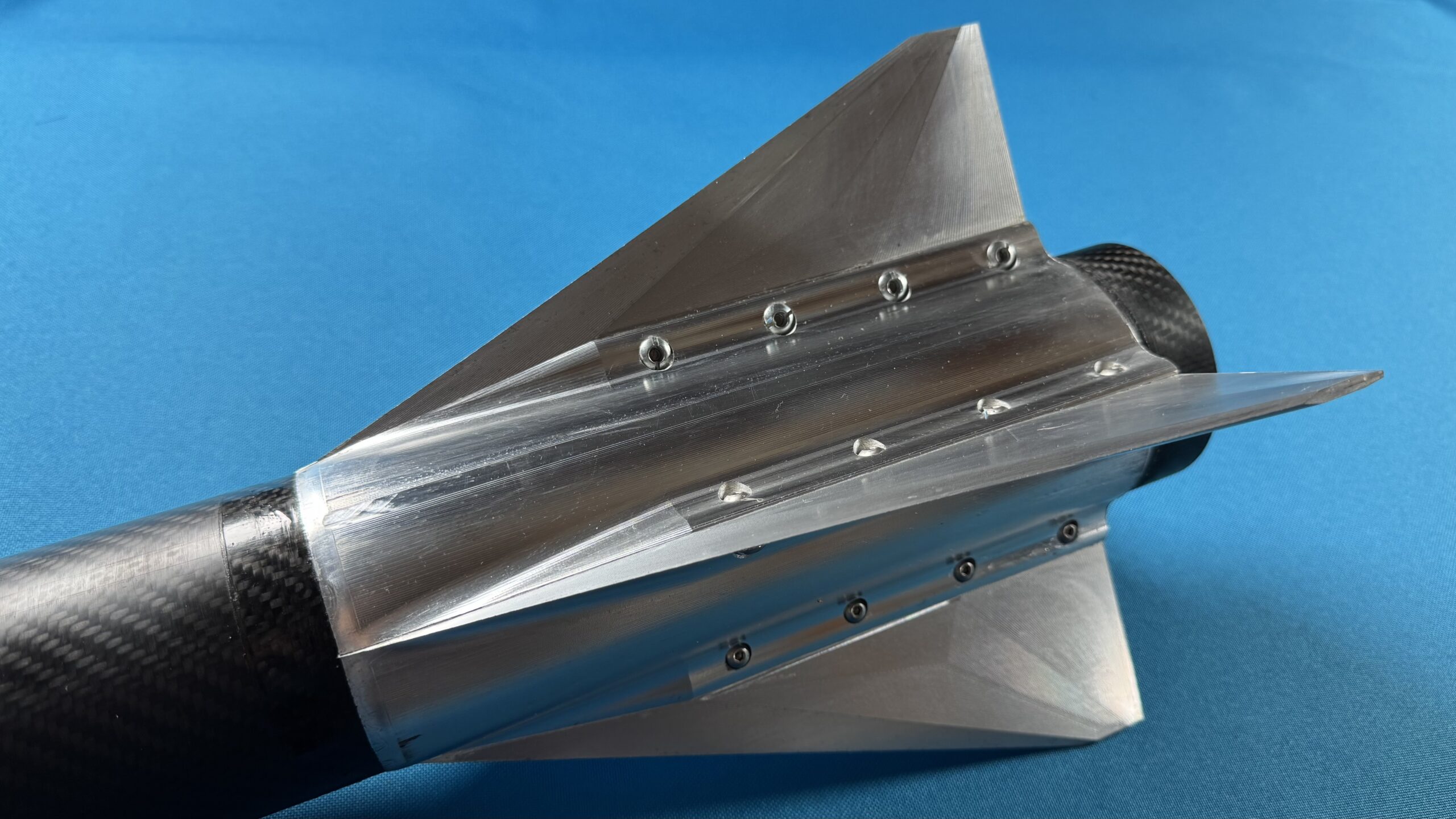

Weight | The original fin assembly weight was ~36lb The goal ‘should’ be to try and reduce the overall rocket weight – but the reality is that this is not a high-performance rocket so shaving a couple of pounds off the fin assembly might not be worth it – unless that allows for a bigger ‘payload’. (Debate) |

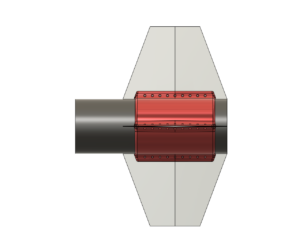

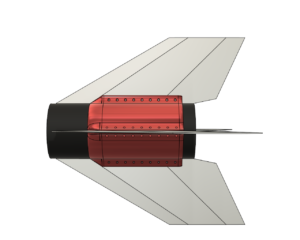

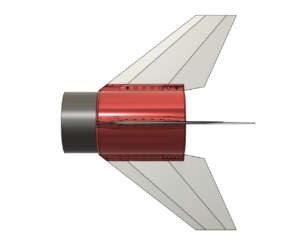

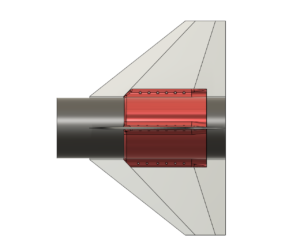

Number of Fins | The proposal is for this to be a 4-fin design – based on original. |

Portability | The preference would be for the fin assembly to be removable to aid in transporting the rocket. |

| Criteria | Description |

1 | Looks Cool / instills that ‘look back’ feeling |

|

2 | Performance |

|

3 | Size |

|

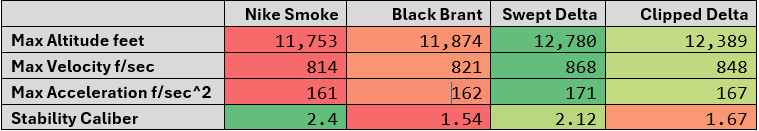

Note: All Performance data is based on simulations that use the Pacific Impulse P8268 motor and the ONLY variable that is altered between designs (in Open Rocket) is the fin assembly design / profile.

Fin Assembly Weight: The original Nike Smoke / Binder Design fin assembly weight was used as baseline and the fin assembly weight for each subsequent design was modified up or down based on the fin surface area percentage relative to this baseline – thus assuming the SAME building material – to keep all things equal.

As a percentage change relative to baseline.

Profile | % change |

Nike Smoke | <baseline> |

Black Brant | +36% |

Swept Delta | -22% |

Clipped Delta | +0.26% |